We are able to proceed with the high value added products upon the basis of our

long experience in titanium dioxide and its chemical-synthetic fiber delustering

technology. As a result of accurated correspondence to meet to rapid and diversifying

customer's change of demand such as higher speed of spinning and denier number

of fibers, we have gained a substantial share in the domestic market. We should

cope with new possibility in titanium dioxide for fiber application to keep our-self

as a leading company in this business area.

|

|

At present time, we are expanding our business area to whole over-seas region followings

to aggressive advancing of domestic fiber manufacturers to foreign countries with

technology transfer. We have already recorded export to more than dozen of foreign

countries and have gained about 50% of market share in Asian countries. Furthermore,

we are striving to accelerate our international market strategy.

|

|

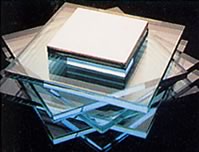

We have developed white pigments for PET (polyethylene terephthalate) film which is the base material for plastic cards. These products are widely used for thin magnetic cards. Further rapid progress is expected in this field, as credit cards, IC cards, and cash cards are becoming thinner. Further, our products are playing an important role in providing brilliantly-colored images for display films, which is a representative example of the film applications.

We have proceeded new functional materials such as vacuum evaporation materials, applying accumulated our own manufacturing and powder handling technology of titanium dioxide.

We have proceeded new functional materials such as vacuum evaporation materials, applying accumulated our own manufacturing and powder handling technology of titanium dioxide.

These advanced functional materials are already commercialized to use for static electricity prevention, electromagnetic wave shielding, optical filter, non-reflective lenses and so on. We are supporting increasing demand in these application fields.

|

We have been producing and selling "Ultrafine particle titanium dioxide" (Micro titanium; Product name: TAF Series) with the primary particle diameter of 0.02~0.01μm. The product, which features not only ultrafine particles, but also a sharp particle size distribution, with few coagulated particles, and excellent dispersibility, is used as the external additive for copy machine toner, filler for special fibers, etc.

|

By-products such as iron sulfate and calcium sulfate are generated from titanium

dioxide manufacturing process. These by-products are also controlled under strict

quality specification to be commercialized. Ferrous sulfate can be used in various

markets such as animal feed, fertilizer, coagulant and deodorizer for sewage treatment,

anti-rusting and so on. While, calcium sulfate is used as a raw material of gypsum

board, and retarder of cement. |

|

Titanium Dioxide Division acquired ISO9001 certification. (August 11, 2006)

We continue quality maintenance of our products because we want our users to use our products satisfactorily. |

|

|

|

Kobe plant (Titanium Dioxide Division) acquired ISO14001 certification. (October 26, 2008)

At Kobe plant, we continue improvement of the produce process through fuel and power saving, and contribute to environmental global protection. |

|

|